Ask any chef about their biggest kitchen regret, and you'll likely hear about that time they ruined a great knife on the wrong cutting board. We love to obsess over knife sharpness, but rarely talk about what's dulling them in the first place. In this article we will guide you through what makes the best wood cutting board and why end grain wood cutting boards stand out.

1. What Makes a Quality Cutting Board

Take a quick look at your current cutting board. Notice any of these warning signs?

- Deep knife marks that collect food particles

- A subtle rocking motion when you press down

- Rough patches that catch your knife mid-slice

- A lingering odor that won't wash away

According to FDA food safety guidelines, these are potential health hazards. More importantly, they're signs your current board is actively damaging your knives.

A quality cutting board preserves your knife's edge, ensures food safety, and provides a stable cutting surface that makes every slice more precise. The difference lies in three key factors: construction method, material choice, and proper thickness.

2. Why Thickness Matters in Wood Cutting Boards

Professional kitchens favor 2-inch thick boards for good reason. The extra thickness prevents warping even with frequent washing and provides crucial stability during heavy chopping tasks. A thicker wood cutting board absorbs knife impact better, protecting both your blade and the cutting surface. The added weight also keeps the board firmly in place during use.

However, being thicker isn't always better for everyone. While 1.5-2 inch boards offer superior stability and longer lifespans, they come with certain trade-offs. The higher price point reflects the additional materials and craftsmanship required. You'll need more storage space, and the increased weight makes them less convenient to move and clean. Some kitchen setups might find the extra height challenging, particularly if you have limited counter space.

3. End Grain vs. Edge Grain Cutting Boards

End grain wood cutting boards typically cost two to three times more than edge grain options, but this price difference could mean significant performance differences. End grain wood cutting board design excels at preserving knife edges through its unique fiber orientation. The board actually "self-heals" from minor knife marks, as the vertical wood fibers close back up after cutting. This same construction provides superior warping resistance and, with proper care, can last over twenty years.

Edge grain cutting boards, while more affordable, don't offer the same level of knife protection or longevity. They require more frequent maintenance to prevent warping and typically last five to ten years with regular use. However, they still provide good performance for casual home cooks.

4. The Best Wood Cutting Board Resists Warping

End grain wood cutting board design fundamentally changes how a cutting board handles moisture. The vertical fiber orientation allows for even moisture distribution throughout the board, while the multiple wood pieces reduce overall movement. When combined with proper thickness, this construction creates remarkable structural stability. Natural expansion and contraction can occur without compromising the board's flatness - a crucial feature for long-term durability.

5. The Best Wood for Cutting Board

Different woods bring distinct advantages to wood cutting board construction.

Teak stands out for its natural oil content, which prevents moisture absorption and minimizes maintenance needs. Its superior density provides excellent stability, though this comes at a premium price point.

Hard maple, traditionally used in butcher blocks, offers excellent durability at a more moderate cost, though it requires regular oiling to maintain its protective properties.

Walnut provides a beautiful middle ground, combining attractive grain patterns with good stability, requiring moderate maintenance to keep its protective qualities.

6. Choosing the Best Wood Cutting Board for Your Needs

For Japanese knife owners, an end grain teak cutting board offers the ideal balance of protection and performance. The vertical wood fibers complement the acute angles of Japanese blades, allowing precise cuts without compromising the edge. Teak's natural density provides the perfect resistance for the pulling motions common in Japanese cutting techniques.

For home cooks using Western-style knives, a hard maple end grain board provides excellent value. Its durability handles heavy chopping while still protecting your edge, and the more affordable price point makes it a practical choice for daily cooking.

Those prioritizing low maintenance might prefer a quality edge grain board in teak. While it won't offer the same level of knife protection as end grain, teak's natural oils make it the most forgiving wood for busy kitchens where regular maintenance isn't always possible.

7. Why Japanese Knives Demand Better Cutting Boards

Japanese knives, with their harder steel and acute edge angles, interact differently with cutting surfaces than Western knives. The Japanese chef knives’ thinner blades can chip or roll when used on improper surfaces. End grain wood, especially teak or maple, provides crucial shock absorption for these precision tools.

The typical Japanese cutting technique - a smooth pull cut rather than a downward chop - benefits particularly from end grain wood cutting board design. As you draw the blade across the board, the vertical wood fibers separate slightly instead of creating resistance. This can preserve the knife's razor edge, allowing for the control needed in Japanese cuisine's precise cuts.

8. Professional-Grade Wood Cutting Board Recommendation

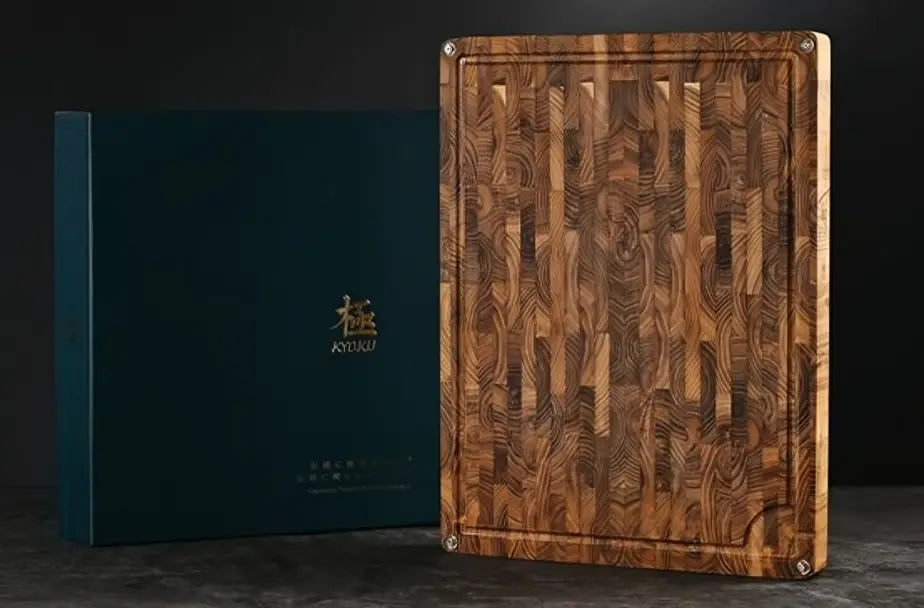

Our top recommendation is the Kyoku End Grain Teak Cutting Board, currently available with special Black Friday pricing.

Key Features:

- Professional-grade 2-inch thickness for maximum stability

- Wide juice groove prevents spills during food prep

- Three built-in ingredient holders double as serving trays

- Natural teak oils resist moisture and bacterial growth

- End grain construction protects knife edges

Available Sizes:

- Compact (17x11"): Perfect for smaller kitchens

- Medium (20x15"): Most popular size, ideal for daily cooking

- Large (24x18"): Professional size for serious home chefs

The medium 20x15-inch board offers the best balance for most home kitchens, providing ample cutting space without overwhelming your counter. For those using Japanese knives or preparing large meals, the 24x18-inch model gives you the extra room needed for proper technique and multiple ingredients.

Conclusion

A quality wood cutting board is an investment in your cooking experience and knife longevity. While premium options like thick end grain cutting boards require a bigger upfront investment, their superior durability and knife-friendly properties often prove cost-effective over time. The right board enhances your cooking experience while protecting your Japanese knives.

The best wood cutting board ultimately depends on your specific situation: your cooking frequency, available kitchen space, willingness to perform maintenance, and budget constraints. Understanding these factors helps ensure you choose a wood cutting board that will serve you well for years to come.